To reinvent an industry, you have to build the best team. Join Formlabs if you want to bring groundbreaking professional 3D printers to the desktop of every designer, engineer, researcher, and artist in the world.

Formlabs products combine electro-mechanical, thermal, fluidic, optical, chemical, and embedded systems to turn computer models into tangible goods. Sustaining Quality engineers are exposed to the full array of subsystems that make Formlabs products reliable and easy to use. This role is broad, spanning field failure analysis, product design revision, test engineering, supplier quality management, and customer service enablement. Sitting within the Product Integrity (quality) organization, Sustaining Quality Engineers interact with customer-facing teams, product managers, product development engineers, manufacturing engineers, sourcing specialists, and suppliers. Data collection and analysis are central to prioritizing work, making decisions, measuring performance, and reporting progress, and our work links directly to the company's bottom line. If you are a generalist engineer, have a passion for data, and enjoy tying your work to boosting customer satisfaction, then join Formlabs’ Product Integrity team as a Sustaining Quality Engineer.

The Job:

- Perform hands-on and data-driven root cause analysis of product failure modes utilizing structured problem-solving methodologies

- Design, implement, and validate product changes to enhance product performance, reliability, ease of use, or cost

- Partner with contract manufacturing partners to develop and implement quality control strategies, ensuring the quality of finished products from piece-part component to arrival at a customer’s door

- Develop and/or issue corrective and preventive actions resulting from nonconforming material escapes to maintain Formlabs’ high-quality standards

- Build expertise in Formlabs' 3D printing technology while collaborating with R&D teams on risk assessment, design reviews, product enhancements, and validation testing

You:

- Have demonstrated experience owning projects over discrete tasks. Can take an ambiguous problem and scope, plan and execute a solution considering various factors from customer experience to operational and design constraints.

- Skilled in investigating complex systems to root cause failure modes across multiple domains - mechanical, electrical, software, manufacturing

- Are well-versed in analyzing data to pick out trends, compare populations, monitor processes, and model system behavior

- Can prototype and run your own tests, from experimental design, sample selection, test fixture development and hands-on implementation

- Exposure to reading and understanding mechanical drawings, 3D CAD systems, electrical troubleshooting tools, and/or mass production manufacturing processes

- Strong technical documentation skills

- A passion for learning new skills, delving into complex technical problems, and building collaborative relationships

Bonus Skills:

- Scripting ability, including python, SQL, bash, and related data analysis tools

- Prior experience in electrical or mechanical design, embedded systems, manufacturing, quality control, or integration engineering

- Training in Lean, Six Sigma, 8D or other structured problem-solving methodologies

- Previous work with contract manufacturing partners utilizing high-volume production processes such as tooled sheet metal, die casting, injection molding, extrusion, SMT PCB assembly

Our Perks & Benefits:

- Robust equity program to build future wealth through RSUs

- Comprehensive healthcare coverage (Medical, Dental, Vision)

- Low cost fund options in our 401K and access to advisors

- Generous paid Parental Leave (up to 16 weeks)

- Tenure-based paid Sabbatical Leave (up to 6 weeks)

- Flexible Out of Office Plan – Take time when you need it

- Ample on-site parking & pre-tax commuter benefits

- Healthy on-site lunches, snacks, beverages, & treats

- Regular sponsored professional development opportunities

- Many opt-in culture events across our diverse community

- And of course… unlimited 3D prints

We are an equal opportunity employer and value diversity at our company. We do not discriminate on the basis of race, religion, color, national origin, gender, sexual orientation, age, marital status, veteran status, or disability status.

Even if you don't check every box, but see yourself contributing, please apply. Help us build an inclusive community that will change the face of 3D printing.

Top Skills

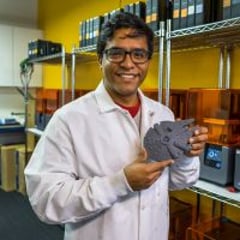

What We Do

We’re a passionate team of engineers, designers, and problem-solvers. Started out of MIT in 2011, Formlabs now employs over 700 people across offices in Germany, Japan, China and Somerville, Massachusetts. We're committed to bringing powerful and accessible fabrication tools into the creative hands of professionals around the world.

Why Work With Us

We’ve built a team 700+ strong across the world, and still counting. We look for people with an insatiable curiosity, a willingness to question the status quo, and a high capacity to get things done.

Gallery

Formlabs Offices

Hybrid Workspace

Employees engage in a combination of remote and on-site work.

Building the 3D tools of the future is not an easy task. To reach this ambitious goal, we need to react fast, iterate, and make changes on the fly. Our teams observe a flexible hybrid, where we all aim to be in office 3 days/week when possible.