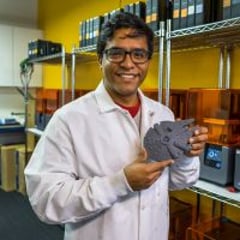

To reinvent an industry, you have to build the best team. Join Formlabs if you want to bring groundbreaking professional 3D printers to the desktop of every designer, engineer, researcher, and artist in the world.

The Print Optimization Team takes on the challenge of optimizing the intersection of hardware, software, and materials to deliver industry leading print performance. We strive to make our SLA & SLS product line print parts as quickly, reliably, easily, accurately, and beautifully as possible. We are a collaborative team, with a diverse background, passionate about pushing the boundaries of print performance across our product lines.

As a 3D Print Optimization Engineer you will be continuously using your problem solving skills to drive improved performance.

We are customer focused, and the first step of tackling the problem is understanding what the performance boost we are trying to achieve, and how many customers will benefit. Will customers be able to print parts faster? More reliability? Will they be easier to post-process, or print more accurately?

If you’re excited about process optimization, solving multi-disciplinary challenges, and bringing to market the best print performance possible, we want you as a 3D Print Optimization Engineer!

The Job:

- Push the capabilities of our SLA & SLS 3D printing platforms

- Drive root cause analysis, considering mechanics, fluid dynamics, software, chemistry, optics, electronics, thermodynamics, and customer behavior

- Design efficient experiments that tease out underlying behavior in a complicated system of variables

- Tackle multi-disciplinary problems

- Develop and commercialize solutions that make a real and immediate impact on customer print performance

You:

- Are focused on the customer

- Have a strong sense of ownership with great attention to detail

- Are hands-on and willing to cross discipline boundaries to solve a problem

- Work autonomously and learn new skills to tackle objective

- B.S., M.S., or PhD in any science/engineering discipline (all are welcome)

Bonus:

- Coding experience, ideally python

- Experienced in computer-aided design (CAD)

- Understand material properties and characterization

- Participated in the release of a new product

Our Perks & Benefits:

- Robust equity program to build future wealth through RSUs

- Comprehensive healthcare coverage (Medical, Dental, Vision)

- Low cost fund options in our 401K and access to advisors

- Generous paid Parental Leave (up to 16 weeks)

- Tenure-based paid Sabbatical Leave (up to 6 weeks)

- Flexible Out of Office Plan – Take time when you need it

- Ample on-site parking & pre-tax commuter benefits

- Healthy on-site lunches, snacks, beverages, & treats

- Regular sponsored professional development opportunities

- Many opt-in culture events across our diverse community

- And of course… unlimited 3D prints

We are an equal opportunity employer and value diversity at our company. We do not discriminate on the basis of race, religion, color, national origin, gender, sexual orientation, age, marital status, veteran status, or disability status.

Even if you don't check every box, but see yourself contributing, please apply. Help us build an inclusive community that will change the face of 3D printing.

Top Skills

What We Do

We’re a passionate team of engineers, designers, and problem-solvers. Started out of MIT in 2011, Formlabs now employs over 700 people across offices in Germany, Japan, China and Somerville, Massachusetts. We're committed to bringing powerful and accessible fabrication tools into the creative hands of professionals around the world.

Why Work With Us

We’ve built a team 700+ strong across the world, and still counting. We look for people with an insatiable curiosity, a willingness to question the status quo, and a high capacity to get things done.

Gallery

Formlabs Offices

Hybrid Workspace

Employees engage in a combination of remote and on-site work.

Building the 3D tools of the future is not an easy task. To reach this ambitious goal, we need to react fast, iterate, and make changes on the fly. Our teams observe a flexible hybrid, where we all aim to be in office 3 days/week when possible.