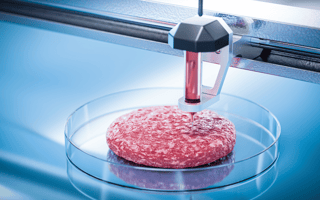

Made out of lab-grown stem cells, 3D-printed meat is an edible rendering of a meat-like product created from an additive manufacturing process. Layer by layer, 3D-printed meat is constructed, or scaffolded, from a bio-ink that extrudes out of a 3D printer nozzle.

These protein-packed prints replicate the look and mouthfeel of conventionally farmed, butchered meat down to a cellular level — to the point where they can be considered “genuine meat” by the Good Food Institute — while being highly customizable and slaughter-free.

What Is 3D-Printed Meat?

Three-dimensionally printed meat is a programmable meat replica made from the additive process of 3D printing that replicates its conventionally farmed counterpart at the cell level.

Aside from profit, establishing the novel technology behind 3D-printed food production has everything to do with meeting a growing demand for meat alternatives, addressing food waste and developing sustainable solutions to combat climate change.

What Is 3D-Printed Meat Made of?

3D-printed meat is made from cultured meat, which means it is lab-grown, cell-based or cultivated. While it’s created from the fat and muscle cells of an animal, the process does not require slaughtering livestock.

“It has the same composition as a raw cut of meat,” Rosalyn Abbott, assistant professor of biomedical and materials science engineering at Carnegie Mellon’s College of Engineering, told Built In. “It has proteins to emulate the structure of the tissue and has fat cells, known as adipocytes, and skeletal muscle cells that provide flavor and texture, respectively.”

Meat substitutes, or plant-based “alt meats,” are also pioneering the 3D-printed meat space. These faux-meat products are commonly created from filament mixtures that combine soy, pea protein, beetroot, chickpeas, coconut fat and even algae proteins, depending on the brand.

How Is 3D-Printed Meat Made?

To begin the 3D-printed meat process, scientists biopsy a batch sample of animal stem cells depending on the desired type of meat — beef, pork, poultry or even fish. These cells then undergo an in vitro proliferation process, bathing in a nourishing, nutrient-dense serum within a climate-controlled bioreactor.

Over the course of several weeks, these cells multiply, interact and differentiate into the fat and muscle cells that make up bio-ink. Then, a robotic arm uses a nozzle to dispense this paste-like, cultured meat filament in fine layers atop one another. The arm follows the instructions of an uploaded digital file using computer-aided design, or CAD, software in order to replicate the correct shape and structure of the intended meat. 3D-printed meat material must be viscous yet firm enough to reproduce a structural model complete with accurate tissue vascularization, depending on the type and cut of meat.

The printed product returns to a second incubation phase, which allows stem cells to differentiate and mature as they would inside of an animal. This is where muscle fibers fully form with the right density, thickness and length now that it has taken shape. After a few more weeks, the lab-to-table meat is ready to be cooked and served.

Some 3D food printers skip this last step by incorporating lasers, which provide a heating element that cooks the food as it prints similar to a crème brûlée torch.

What Are the Pros of 3D-Printed Meat?

If readily available food at the press of a button isn’t enough of a selling point, here are a few standout features attributed to 3D-printed meat.

Customizable

The foremost benefit of 3D-printed foods is in its customizability.

“You can control the shape, structure, flavor profile and nutritional value of a food by carefully integrating different ingredients into the 3D printing process,” food scientist Bryan Quoc Le told Built In. “This is especially important for the cultured meat industry, where differences in texture, taste and color are essential for producing meat products on par with the conventional meat industry.”

Scalable

Le, who is also author of 150 Food Science Questions Answered, also noted accessible scalability to these tailor-made meats without forfeiting personalization. “Each food item is more or less the same,” he said, “but it also offers the ability to customize en masse.”

Slaughter Free

Biotech scientists have figured out how to harvest stem cells from livestock while keeping the actual animal alive. Aside from this being a win for people who are against the consumption of animals, this practice shows promise in addressing a growing global demand for animal proteins related to an increasing population, rising incomes, urban sprawl and aging communities.

Environmentally Friendly

Traditional agricultural practices are the foundation of the world’s food supply chain, but come at a great cost. As summarized by online science publication Our World in Data, the resource-intensive industry of food production requires large amounts of fresh water, significant land use — more specifically, half of the world’s habitable acreage — and is responsible for more than one-quarter of greenhouse gas emissions.

This is where cultured-meat harvests and 3D printing tech can help.

“Currently, the majority of livestock are reared in concentrated animal feeding operations causing environmental, public health and food security concerns,” said Abbott, who co-leads a project team researching the feasibility of 3D-printing high-end cuts of cultured meat. “Three-dimensionally printed meat will reduce agricultural land use, water consumption, greenhouse gas emissions and improve energy efficiency.”

Quicker to Produce

Cultured meat also takes a matter of weeks to produce, compared to the years required in raising livestock, Abbot added.

What Are the Cons of 3D-Printed Meat?

Food printing technology is relatively new. So, the primary disadvantages are relative to things like speed and scale — low throughputs skews efficiency of 3D-printed meat production — as well as unknowns around consumer reception.

Costly

A lab at Konkuk University estimated the cost to produce cultured meat at about $700 per kilogram, Advanced Science News reported.

As for equipment, the average cost of a 3D-food printer ranges between $1,000 to $5,000, according to additive manufacturing marketplace Aniwaa. However, this excludes the industrial-sized, food-grade machines specialized to meat production currently in use by companies pioneering the space.

From a diner’s perspective, the price tag for a cut of 3D-printed steak can go for £20 to £30 at already-rolled out locations such as London-based restaurant Mr. White’s or even astronomically higher at $900 for the Wagyu variety.

Difficult to Produce

Comparative to other 3D-printed foodstuffs, like chocolate or pasta, 3D-printed meat ranks low in its printability, according to an article in Current Research in Food Science. As you can imagine, it’s a lot easier to control the melting and molding point of a fudge-based treat than it is pureed chicken. And, in order to retrieve this pureed protein, there’s an entire tissue engineering, pre-processing stage before it can be considered cartridge-ready.

Additionally, meat-specific 3D printers require more development before they can ensure food safety at every step. Unlike other products, meat materials are prone to microbial growth and spoilage if not handled with care.

Regulatory Challenges

Food regulations are still coming around to allow 3D-printed meat into the market.

Regulatory frameworks specific to 3D-printed meat from the Food and Drug Administration and the United States Department for Agriculture remain an ongoing development. 3D-printed meat can be considered a “novel food” according to the FDA, in which a clear regulatory pathway for the production of cell-cultivated meat has been in the works since 2019.

That said, Berkeley-based UPSIDE Foods, a startup that grows cultivated chicken meat, became the first to pass a pre-market consultation from the FDA for a human food product made from cultured animal cells. In 2023, it also received full regulatory approval from the FDA and USDA to produce and sell its cultivated chicken product.

Examples of 3D-Printed Meat

Good Meat’s Chicken

GOOD Meat, a brand operating under the food company Eat Just, focuses on creating cell-cultivated, 3D-printed chicken. Its process involves extracting animal cells from a chicken egg or living chicken and immersing them in a nutrient substance to help them grow. After four to six weeks of growth, the cells are then harvested and 3D-printed into their intended chicken cutlet shape. GOOD Meat bills itself as the first company in the world to sell cultivated meat, and has its products approved for sale at select restaurants in the U.S. and Singapore.

Revo Foods’ Salmon Filet

Revo Foods is an Austria-based company selling plant-based, 3D-printed seafood products in countries across Europe. Its salmon filet product, known as “THE FILET,” is entirely vegan and printed using fungal protein, plant oils and algae extracts. These ingredients allow the filet to retain high protein and vitamin content, and provide a similar texture to that of real salmon. Along with its salmon filet, Revo Foods also creates plant-based smoked salmon, gravlax, fish spreads and 3D-printed octopus cuts.

Aleph Farms’ Ribeye Steak

Israel-based Aleph Farms bioprints cow cells to create a slaughter-free cut of ribeye steak. This 3D-printed replica is a particularly thick, fattier cut with heavy marbling as a nod to the “real” thing — no genetic engineering necessary. During the incubation process, “cells continue their development and interaction in a similar manner to what happens inside the cow’s body,” the company said in a blog post. According to its website, Aleph Farms introduced the world to the first 3D-printed steak in 2018 — a thinner cut that led to the ribeye’s debut in 2021. In January 2024, Aleph Farms received the world’s first regulatory approval for cultivated beef steaks from the Israel Ministry of Health, granting it the ability to produce and market its steak product in Israel.

Osaka University’s Wagyu Beef

Researchers at Osaka University in Japan are taking on the challenge of replicating the unique mouthfeel of Wagyu, a beef cut known for its rich flavor and buttery tenderness. The team of scientists developed a 3D-printing method that mimics Waygu’s high-fat, intramuscular tissue structure — including muscle fibers, fat and blood vessels — to synthetically reproduce its signature texture.

Shiok Meats’ Shrimp Dumplings

Headquartered in Singapore, Shiok Meats creates cell-based, cruelty-free “clean meats.” In 2019, the company launched its debut dish, eight shrimp dumplings. As a note to CEO and co-founder Sandhya Sriram’s Asian heritage, Shiok Meats specializes in seafood — differentiating itself from beef-centric startups in the space. Currently, its lab harvests stem cells from shrimp, crabs and lobsters and cultivates them using cellular aquaculture technology.

Steakholder Foods’ Omakase Beef Morsels

Formerly known as MeaTech, Steakholder Foods debuted their highly marbled, 100-percent cultured beef morsels in 2022. These Wagyu-beef inspired squares stack layers of muscle and fat tissue sourced from bovine stem cells, and can be programmed to any desired sequence of marbling, shape or width. This same tech can be applied to other protein-powered plates, spanning burgers, kebabs, meat loaf, meat pies as well as hybrid-meat products, featuring both lab-grown meat and plant-based ingredients.

Redefine Meat’s Tenderloins

Purely plant-based, Redefine Meat’s product line offers a lean and smooth cut of its faux-beef tenderloin. Taking note of color gradations and texture, this butchered-meat alternative makes roast and filet mignon accessible for both meatless and carnivorous palates. The entirety of Redefine Meat’s portfolio is strictly vegan, meaning that none of their 3D-printed meat products are sourced from cultured meat or utilize any animal byproducts. Instead, the company’s ingredient list consists of soy and pea proteins, chickpeas, beetroot, nutritional yeasts and coconut fat used to create their brand of “new meat.”

Frequently Asked Questions

What is 3D-printed meat made of?

3D-printed meat is made of cultured meat (also known as lab-grown, cell-based or cultivated meat). Cultured meat is grown in a lab using an animal's stem cells, and does not require slaughtering animals.

How is 3D-printed meat made?

3D-printed meat is made by having animal stem cells undergo in vitro cell proliferation inside a bioreactor for several weeks, where they multiply and differentiate into fat and muscle cells. This cell filament is then dispensed into the shape and texture of meat, which becomes re-incubated then cooked.

Is 3D-printed meat safe to eat?

3D-printed meat is safe to eat as long as it is prepared and cooked properly, similarly to other meats.

Is 3D printing meat sustainable?

3D printing meat may be a sustainable meat production option. The process can reduce land usage, energy usage, fresh water consumption and greenhouse gas emissions in comparison to traditional meat production.

Does 3D-printed meat taste the same?

3D-printed meats aim to replicate the taste and texture of their real meat counterparts, whether it be chicken, beef, pork or seafood.